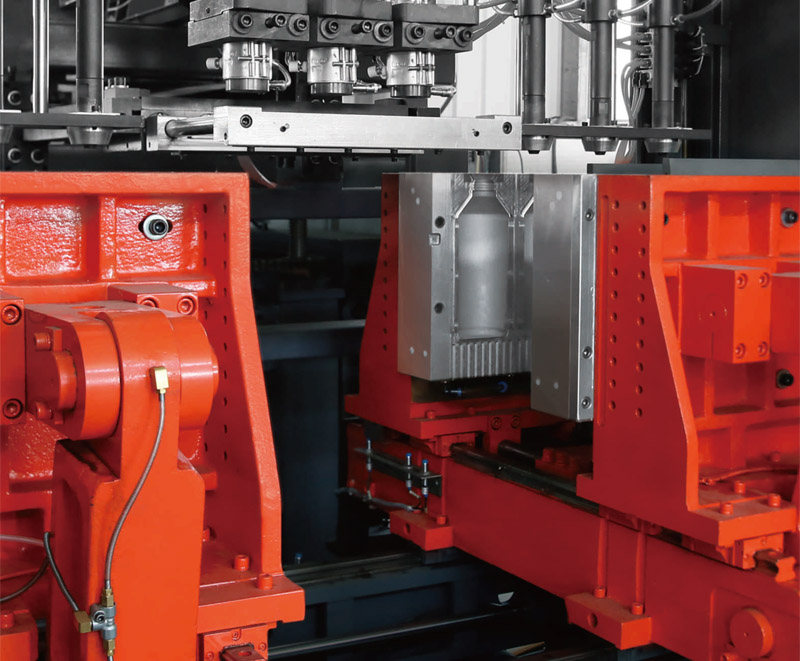

HDEP extrustion blowing machine

20-30 Liter Automatic Extrusion Blow Molding Machines

Double stations and linear guide movement, high intensity stainless steel mould platens, driven by hydraulic pressure, designed and analyzed by finite element aided software, ensure big clamping force, no expansion of mold.

High span central supporting mould platens make the movement stable and less wearing; central clamping with large mold open stroke ensures the even clamping force and keeps the mold platens in deformable.

Specially designed screw with high L/D ratio insures good plasticizing and stable extrusion; high precision and no part line die head guarantees customers’ top-quality requirement.

Multi-screw & multi-die head can be adopted to improve the quality of the product and lower down the cost of material.

Double stations and linear guide movement, high intensity stainless steel mould platens, driven by hydraulic pressure, designed and analyzed by finite element aided software, ensure big clamping force, no expansion of mold.

High span central supporting mould platens make the movement stable and less wearing; central clamping with large mold open stroke ensures the even clamping force and keeps the mold platens in deformable.

Specially designed screw with high L/D ratio insures good plasticizing and stable extrusion; high precision and no part line die head guarantees customers’ top-quality requirement.

Multi-screw & multi-die head can be adopted to improve the quality of the product and lower down the cost of material.

Famous brand of vector inverter in high pulling torque, complied with special extrusion hardened reducer, can operate in stable, durable, and low noise state.

All hydraulic parts are from Yuken (Japan) . Pressure & proportional control are set by PLC, which ensures the stable operation ; Mold movement is controlled by special speed limited valves, ensuring precise position and non-striking.

Parts of pneumatic system are imported from FESTO (Germany), SMC (Japan), etc, which are top brands in the world. These make sure the operation of machine reliably and accurately; the air circulation is large while the leakage is very small.

High speed Siemens (Germany) PLC with multiple language touch screen, easy-access menu display, is easy to control and operate.

Schneider (France) touchless sensors and switches are adopted, which are dependable and in low heat, & prolonged life.

Multiple-way PID controlled temperature heating is precise and stable. . Parison controller is optional to reach high quality products and reduce cost.

Fully automatic operation can be achieved by optional equipments like auto-deflashing, rotary trimming device, or separated rotary trimming equipment

| TYPE | Unit | BG-S30L | BG-S60L | BG-S80L |

| Max. Product Volume | L | 30 | 60 | 80 |

| Dry Cycle | Pc/H | 600 | 450 | 360 |

| Screw Diameter | MM | 80 | 90 | 100 |

| Screw L/D Ratio | L/D | 26:1 | 26:1 | 28:1 |

| Screw Heating Capacity | KW | 6-8 | 7-9 | 8.5-10 |

| Clamping Force | KN | 200 | 230-300 | 300-400 |

| Number of heating zone | Zone | 4 | 4 | 5 |

| Output of HDPE | Kg/Hr | 100-120 | 140-200 | 180-260 |

| Oil Pump Drive Power | KW | 22 | 30 | 35 |

| Mold Stroke | MM | 140-380 | 150-480 | 160-550 |

| Size of Mold | (W*H)MM | 550*650 | 700*900 | 800*1000 |

| Max. Die pin Diameter | MM | 300 | 350 | 430 |

| Blowing Pressure | Mpa | 0.8 | 0.8 | 0.8 |

| Air Volume | M3/Min | 0.8 | 1.0 | 1.2 |

| Cooling Water Pressure | Mpa | 0.3 | 0.3 | 0.3 |

| Water Consumption | L/Min | 60 | 85 | 100 |

| Weight of Machine | T | 10 | 12 | 15 |