Jars / Wide-mouth PET Blow Molding Machine

Fully Automatic Wide Mouth Bottle Jar Stretch Blowing Molding Machine

Machine Features:

Low labor and energy cost, high efficiency and profit, with automatic bottle embryo delivery process.

The blow molding machine has automatic alarm, automatic fault detection and judgment function, easy and fast maintenance.

Omron, Festo, Parkers are our accessories suppliers.

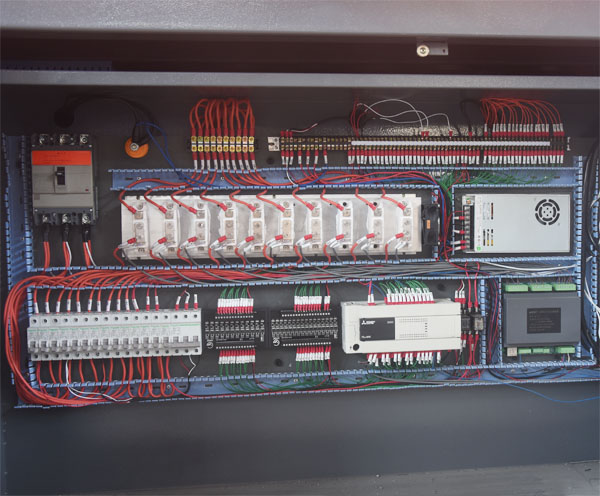

Easy operation and stable performance with Mitsubishi or Siemens human-computer interface control program.

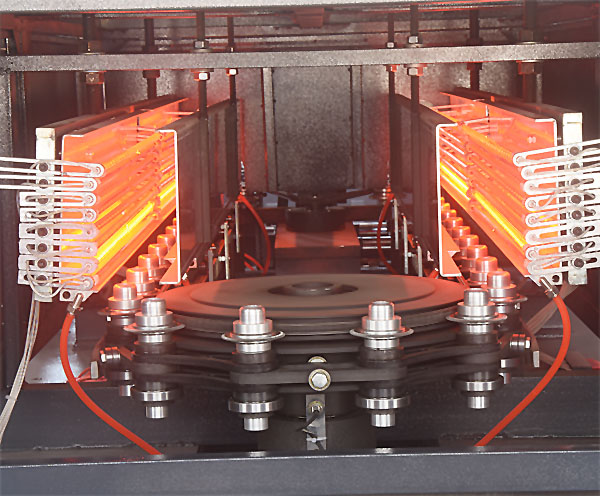

Strong penetrability, even heating and energy saving with Philips infrared lamp.

The blow molding machines are widely used in the production of mineral water bottles, edible oil bottles, food packaging bottles, daily chemical bottles, agricultural medicine bottles, and many other plastic container packaging fields.

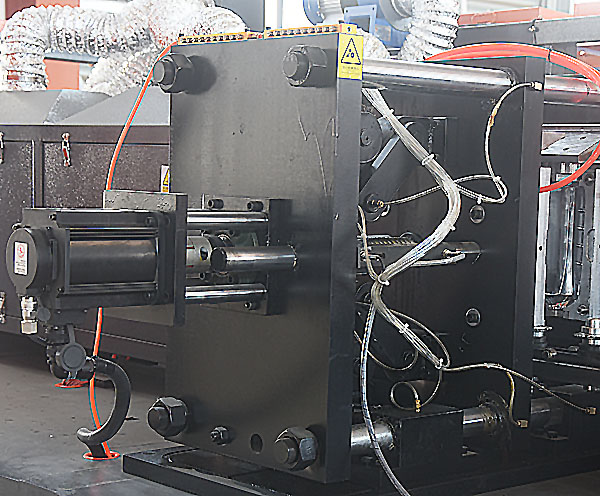

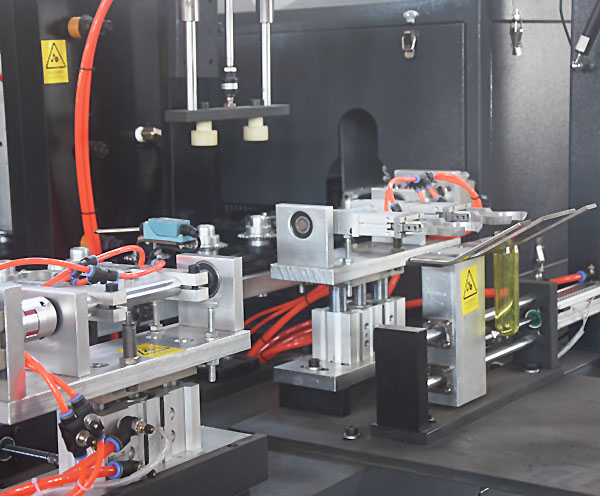

Borg mould locking mechanism guarantees big clamping force, no expansion of mould, no increase of high pressure air consumption.

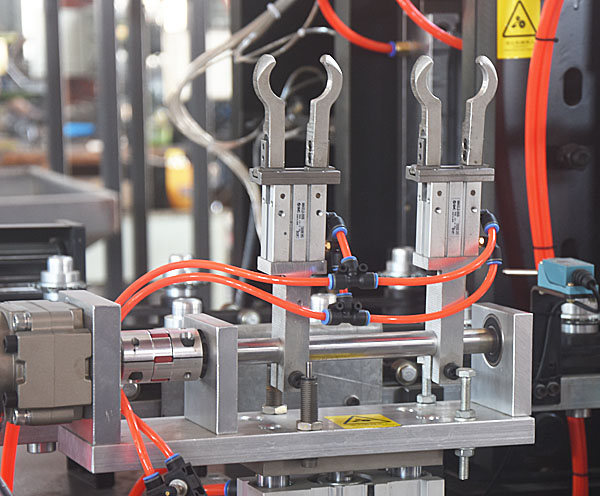

Sliding transferring guarantees stable, fast and accurate operation.

Self-locked high pressure sealing makes stable sealing, no impact, and no wearing. Indepentant controlled stretch bar provides accurate stretching.

Automatic preform handling equipment and robots for perform loading & take-out make production process fully automatic.

Latest high speed PLC and Chinese-English HMI are adopted. The time setting can be accurate in 0.01 second. It makes the operation more easy and the technical setting more accurate.

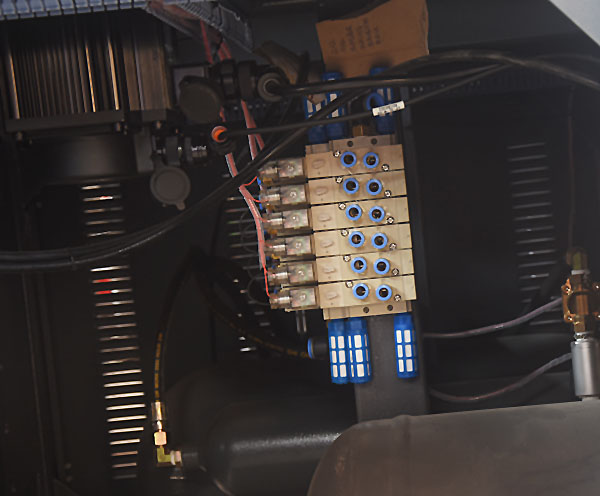

High quality pneumatic parts are imported from Europe or Japan. Fast feedback solenoid valve (from Germany) is adopted in high-pressure blowing. It ensures the second blow time accurate and controllable.

Centralized heating makes even, stable effect, and reduces power consumption mostly.

Close-loop heating control system with corresponsive high accurate digital meter, and imported adjustable high power frequency controller, make sure stable heating, energy saving and not to be affected by fluctuated voltage. IR lamp which is most efficient for PET heating, is fully considered for lower power consumption and higher production efficiency.

| project | BG-2000-2 | BG-2000-3 | BG-2000-4 |

| Theoretical output | 2000 | 3000 | 4000 |

| Maximum capacity of bottle | 2L | 2L | 2L |

| Maximum outer diameter of bottle mouth | 110mm | 110mm | 110mm |

| The maximum diameter of the bottle | 110mm | 110mm | 80mm |

| Maximum height of the bottle | 320mm | 335mm | 320mm |

| Number of cavities | 2 | 3 | 4 |

| Number of lamps | 40 | 50 | 60 |

| Maximum heating power | 60kw | 75kw | 90kw |

| Machine installed total power | 65 | 82 | 97 |

| Actual power consumption | 35kw | 40kw | 47kw |

| Working low pressure | 0.7Mpa | 0.7Mpa | 0.7Mpa |

| Low-pressure gas consumption | 1400Lre/min | 2000Ltr/min | 2000Ltr/min |

| Blowing bottle high pressure | 3.5Mpa | 3.5Mpa | 3.5Mpa |

| High-pressure gas consumption | 3500Ltr/min | 5250Lte/min | 5000Ltr/min |

| Chiller pressure | 0.3-0.5Mpa | 0.3-0.5Mpa | 0.3-0.2Mpa |

| temperature range | 10.C | 10.C | 10.C |

| consumption | 30L/min | 40L/min | 40L/min |

| Machine size | 2.7X1.8X2.2m | 3.6x2x2.2m | 4.5x2.2x2.2m |

| Machine weight | 3500T | 4800T | 5500T |

1.Cooperated Brand

2.MAIN COMPONENTS

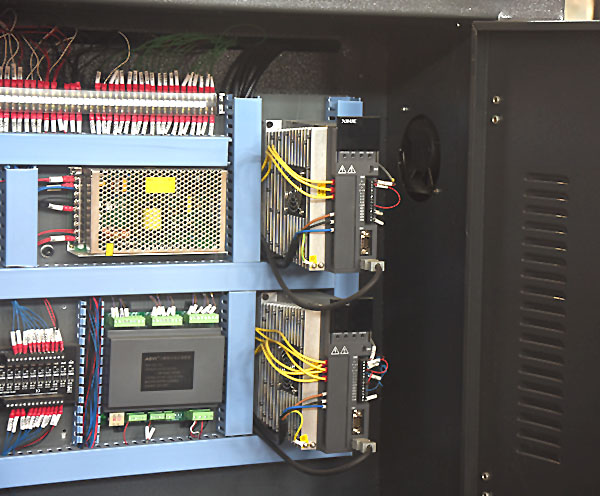

Private server host.

PLC control Brand: Mitsubishi Option Brand: Siemens

Infrared heating lamp tube Ruby Lamp

Central Processor.

Mold lock.--Servo motor system

Cylinder MSC

Flip the cylinder,festo...

Blowing vale Fisto..