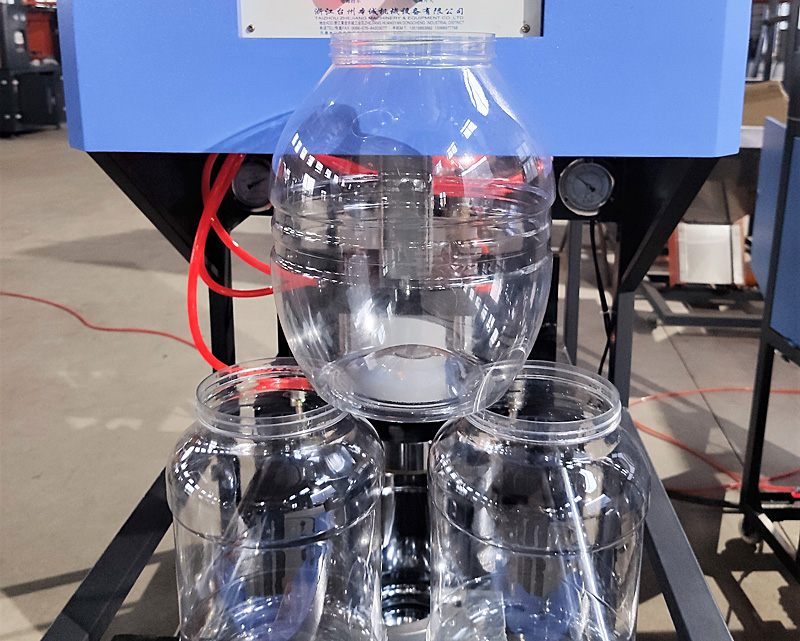

5L-25L Semi-Auto bottle blowing machine

5L-2 5Gallon Semi-Auto Blow Moulding Machine

Advantages of PET Bottle Blow Moulding Machine

1. Semi-closed heating structure, even perform heating, low reject rate.

2. Man-Machine Interface control panel simplified operation.

3. High pressure air recycle system, which can save about 50-60% high pressure air, and save investment for low pressure air compressor, reduce energy lost.

4. Stable machine structure, low noise.

5. Drawer mould-fix structure facilitates mould exchange for different bottle shape.

6. Linear structure, modular design, easy maintenance.

7. The filling temperature can be up to 95ºC

PET Bottle Blow Moulding Machine is one of high-quality Blowing machines made by Bg PET Bottle Blowing Machine Supplier and Manufacturer from China.

1. Introduction:

pet bottle blow moulding machine price is suitable for producing PET/PE and PP plastic containers

And bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle Oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

2. Our advantage:

1)High safety. High speed with high efficiency.

2)Manual saving, one man is enough for operation the machine.

3)Stable performing with easy maintaining.

4)Imported PLC controlling and man-machine interface computer.

5)Japan Omron inspection sensor.

6)Adopt the new type double bend arm and the four rod-clamping structure(won the patent): Cross direction; Middle mould board is move parallel; The distance between two mold board is adjusted by the chain wheel. Thus, the clamping force is very strong.

7)Power saving design that can increase your profits.

8)Segregate type air controlling system, which is designed for avoiding waste pollution.

9)Perfet after-sale service. We can offer you spare parts for free at the first year.

| ITEM | BG-5L-2/ BG-10L-1 |

| PRODUCT VOLEME | 5--10L |

| PRODUCT CAVITY | 2 |

| PRODUCTION CAPCITY | 5L-2CAVITY 800-900 10L -1 CAVITY 600-800PCS/HR |

| PRODUCT DIAMETER | 28-120MM |

| MAX DIN | 300MM |

| VOLTAGE POWER | 380V/3PH/50-60HZ |

| MIN AIR COMPRESSOR | 1.6CM3/3.0MPA |

| TEMPLATE SIZE | 480*660MM |

| MOLD THINKNESS | 350--420MM |

| CLAMPING FORCE | 80KN |

| OPERATING PRESSURE | 8-10BAR |

| BLOWING PRESSURE | 30BAR |

| MACHINE TOTAL POWER | 10-15KW |

| MACHINE WEIGHT | 1000KG |

| MACHINE SIZE (L*W*H) | 2.3*0.8*2M |

| HEATER POWER | 10KW |

| HEATER WEIGHT | 800KG |

| HEATER SIZE (L*W*H) | 2.7*0.6*1.7M |