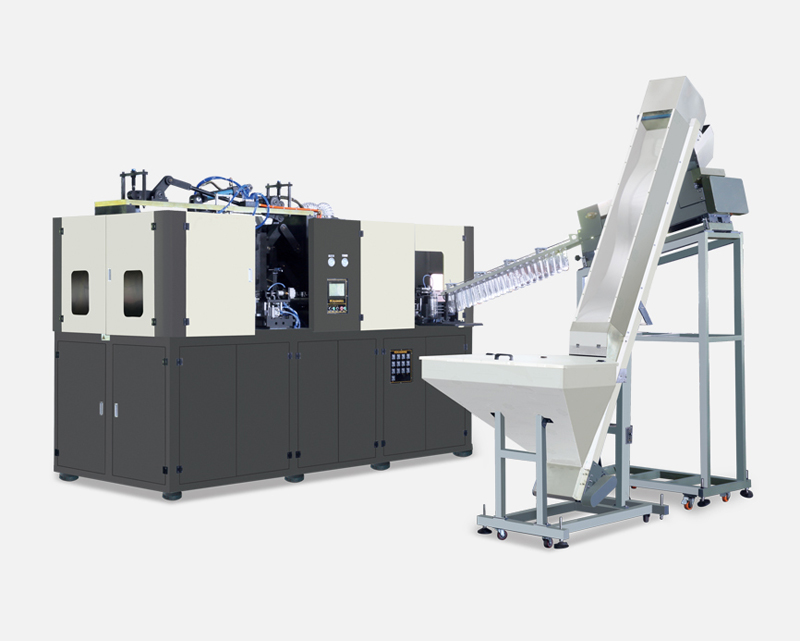

Full-Auto Bottle Blowing Machine(10L-20L)

20L pet bottle Automatic Blowing Machine OEM Bottle Germany Stretch Cylinder Power

10/20L PET Bottle Making Machine – Big Bottle Blowing machine

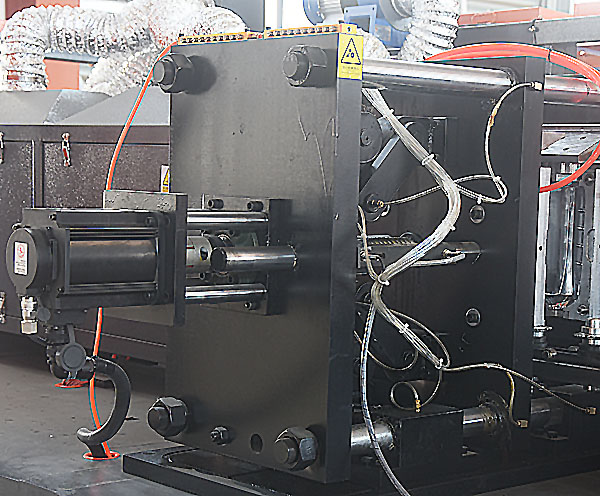

This PET bottle blowing machine is a two step fully automatic blow moulding machine specially designed for 20 liter edible oil bottle production,best choice for productions with big volume,high speed and full automation.It has 2 cavities with up to 20 liters for each cavity,suitable as welll for other bottles above 2 liters ,like carbonated drinks,low-middle tempeprature juice beverage,mineral water and pestcide,etc.

Characteristics of automatic blow molding machine:

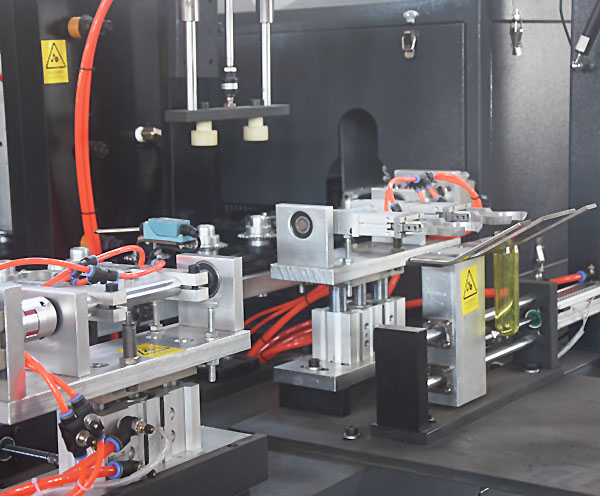

1. Avoid the danger of semi-automatic manual bottle extraction, reduce the loss caused by the accident, and improve the production efficiency.

2. Labor saving: the machine can be operated by a single person or multiple machines at the same time, saving 3 to 4 times the labor force.

3. Stable performance: It adopts imported touch screen man-machine interface computer, which has fast performance and strong stability. The structure is simple, the oven is integrated with the slide way in the main body, and the maintenance is convenient.

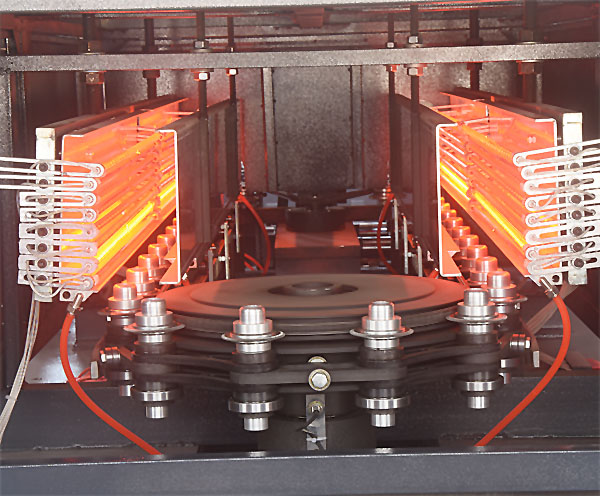

4. Infrared lamp tube is used for heating and heating uniformly, and a reasonable ventilation and cooling system can ensure the preform heating and the cooling of the container mouth are stable. The PLC has independent temperature control in sections, the design of the drying tunnel is reasonable, can be turned over, and can be adjusted up and down. The preform heating center distance is small, and the heating speed is fast. The preform enters the oven, the bottleneck is upward. Due to the oven cooling and ventilation system, the bottleneck and the shaft will not overheat the surface of the preform, even the thick preforms and products can be cooled well, avoiding being crystallized. In order to ensure the yield of bottle blowing, the oven is in a more important position in measuring the performance of the machine. The temperature control adopts automatic feedback and closed-loop adjustment mode.

5. The detection element is selected from Japan's Omron omron electrical appliances, and the strong power control is selected from imported famous products with reliable performance.

6. With automatic alarm and automatic fault detection and judgment kinetic energy.

7. It can store a variety of different bottle blowing process parameters. When replacing different molds and preforms, it can be directly retrieved from the computer without readjusting the data, and the operation is simple.

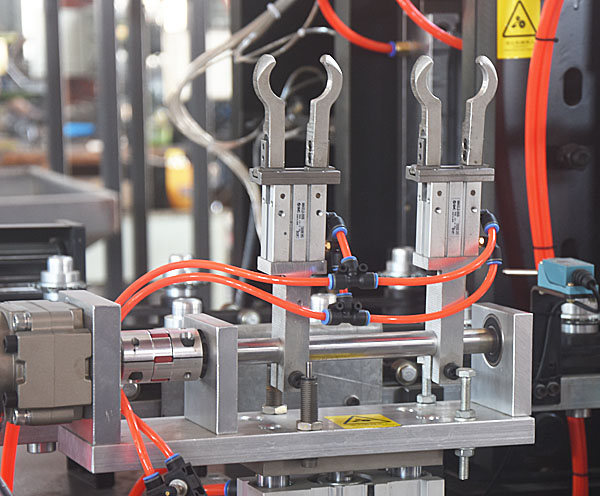

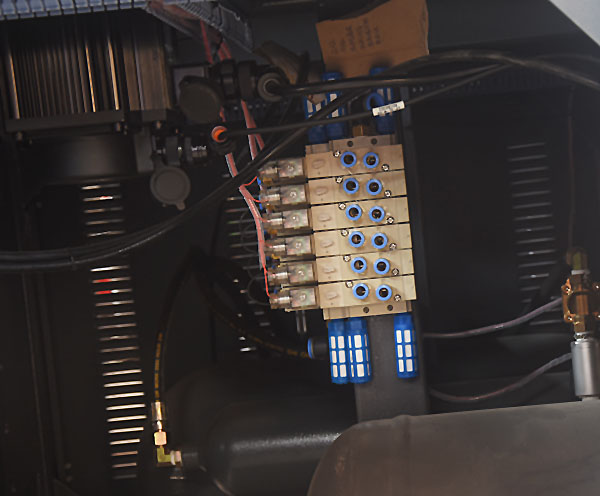

8. Use pneumatic components imported from Germany, Japan and Taiwan.

9. It has high sensitivity, fast switching speed, low failure rate, and reliable operation. The super-standard anti-vibration overall structure adopted by the whole machine reduces the vibration to low under the condition of high-speed operation of the machine, extending the accessories Service life.

10. The air path design action and blowing are divided into two parts to meet the needs of different air pressures for bottle blowing and action, and to achieve high pressure blowing products. Optional blower exhaust recovery system.

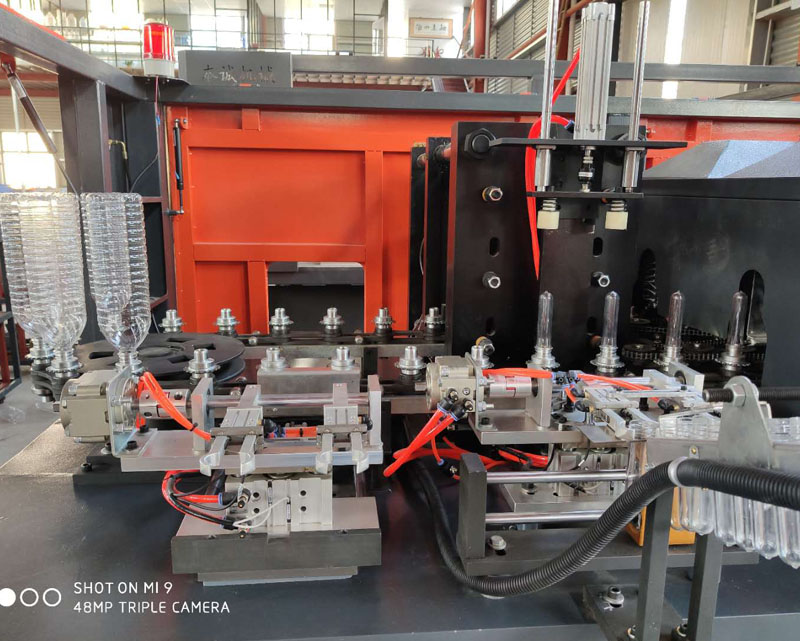

11. It adopts double toggle, the main link hinge mechanism has strong mold clamping force, and has the function of mold clamping and pressurization during high-pressure bottle blowing, and the action is stable and reliable.

12. The moving parts of the mold opening and closing adopt linear guide rails, which have abrasion resistance, and the mold opening and closing operates smoothly and without vibration.

| TYPE | ITEM | BG-20L |

| Product parameters | Maximum capacity | 20L |

| Number of cavities | 1Cavites | |

| Yield | 300-600pcs/hr | |

| Maximum caliber | 65mm | |

| The maximum diameter | 360mm | |

| maximum height | 540mm | |

| Power specifications | Number of lamps | 39pcs |

| Maximum heating power | 100kw | |

| Total power of the machine | 120kw | |

| Actual power consumption | 18kw | |

| Air pressure specifications | Working pressure | 0.7-0.9mpa |

| Low voltage power consumption | 2600ltr/min | |

| Blowing pressure | 2.5-0.5kg/c㎡ | |

| High voltage power consumption | 4000ltr/min | |

| Cooling water specifications | Working pressure | 0.3-0.5mpa |

| Humidity range | 10.c | |

| consumption | 50L/min | |

| Appearance specifications | Machine size | 4.1*1.8*3.0m |

| Machine weight | 6.5T |

1.Cooperated Brand

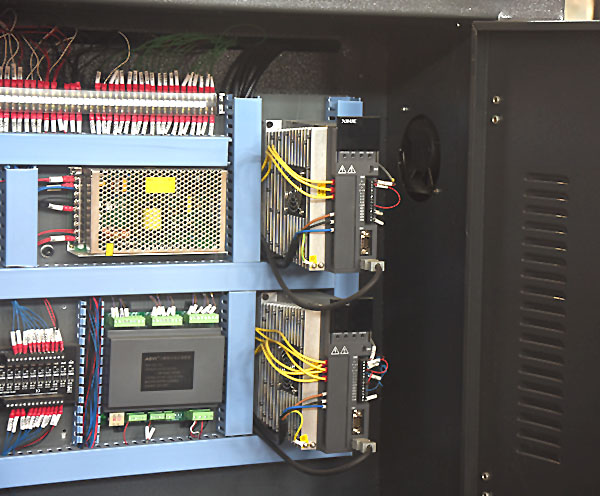

2.MAIN COMPONENTS

Private server host.

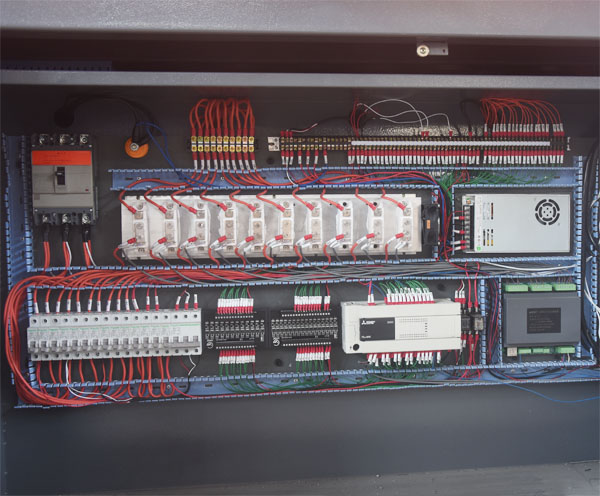

PLC control Brand: Mitsubishi Option Brand: Siemens

Infrared heating lamp tube Ruby Lamp

Central Processor.

Mold lock.--Servo motor system

Cylinder MSC

Flip the cylinder,festo...

Blowing vale Fisto..