Blog

What are the requirements for mold selection?

Mold material selection is a very important part of the entire mold making process. Mold material selection needs to meet three principles. The mold meets the work requirements of wear resistance, strength and toughness, the mold meets the process req...

Application of Blow Molding Machine

Blow molding machine is a kind of hollow container made of plastic particles through a blow molding process. It is currently a relatively common model including a hollow extrusion blow molding machine that uses PP and PE for one-time molding, and uses...

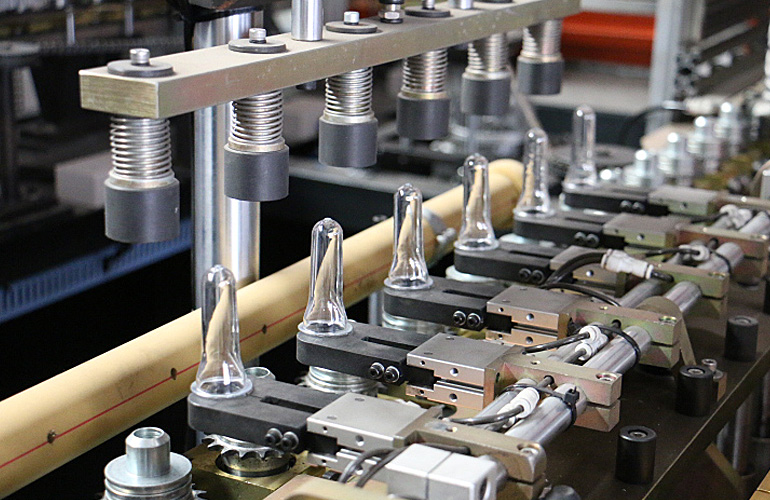

PET bottle blowing machine technical problem solution

The blow molding machine blow molding process is a two-way stretching process in which the PET chain is bidirectionally extended, oriented and aligned, thereby increasing the mechanical properties of the bottle wall and improving the tensile, tensile ...

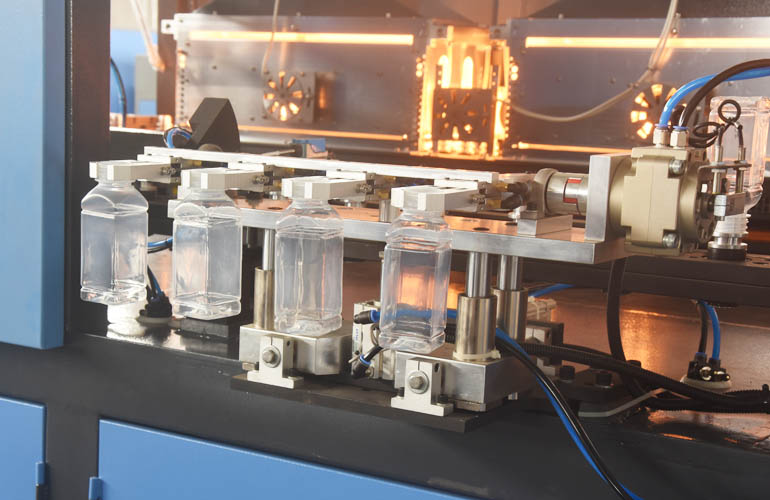

Borg Pet Bottle Blowing Machine, Pet Blow Moulding Machine

With the global market of packaged Water, Beverage and other liquid food growing at a rapid rate. PET stands as a perfect solution to replacing glass in the industry.PET has all the advantages of strength as it is rugg ed, unbreakable along with its u...

Three Factors Influence the Taste Of Water

There are three factors that affect the taste of water, namely, carbonation, TDS value and PH value. Which the level of TDS value of the water taste the greatest impact, followed by carbonation, and PH value of the impact is minimal.

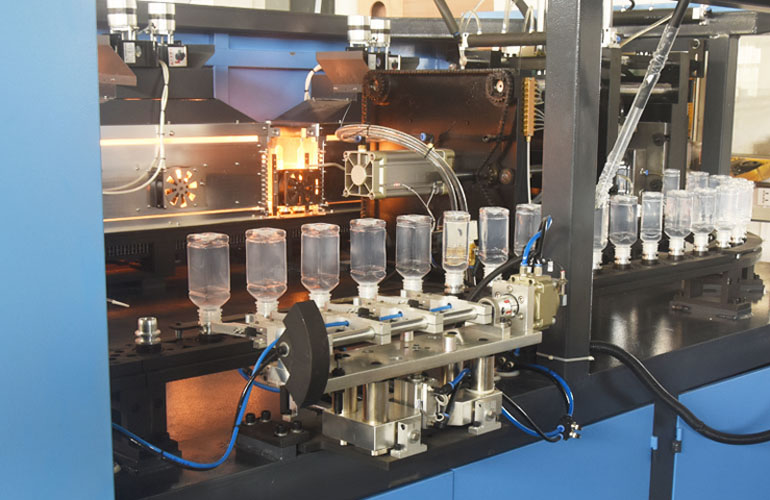

What is Blow Molding Machine?

Hollow blow molding is the most important forming technology for producing hollow plastic products. Almost all thermoplastics can be used for hollow blow molding, such as polyethylene, PVC, polypropylene, polystyrene, linear polyester, polycarbonate, ...

Some Common Recycling Signs In Plastic Products

Each plastic container has a triangular logo with 7 digital numbers inside. Each number represents a type of plastic material, which is like an “identity card” for plastic products. It is mainly used for classification when recycling plastic product...

Blow molding machine combination features

The blow molding machine is a comprehensive hollow plastic hollow blow molding machine that combines the injection plasticizing mechanism of the injection molding machine with the blow molding and clamping mechanism of the hollow blow molding machine,...

Blowing type automatic blow molding machine machine features

A. Adopting the microcomputer control system to improve the predecessors, the function is not chaotic;B. The conveyor automatically feeds the billet;C, using infrared lamp heating, strong penetrating power, preform rotation and heating, track revoluti...

Maintenance method of plastic hollow blow molding machine

1. The main components of the blowing machine are maintained. It mainly includes a series of environmental protection parts such as moisture-proof and anti-corrosion of electronic control components, convenience of switching between lines, stability p...