HOME

Which 6-cavity blow molding machine manufacturer is better? what is the price?

One-out six-blow molding machine is the first choice for upgrading bottle production in many small and medium-sized water plants, mineral water and beverage factories because of its large number of mold cavities and high output.

Read More

What are the advantages of plastic blow molding machine?

With the continuous development of society, more and more people use plastic blow molding machines, especially in the food and beverage industries. The edible oil bottle series linear blow molding machine of China BORG Machinery is a special blow molding machine for 5 liters of edible oil. The specially developed two-step automatic blowing equipment for bottles can meet the needs of customers for l...

Read More

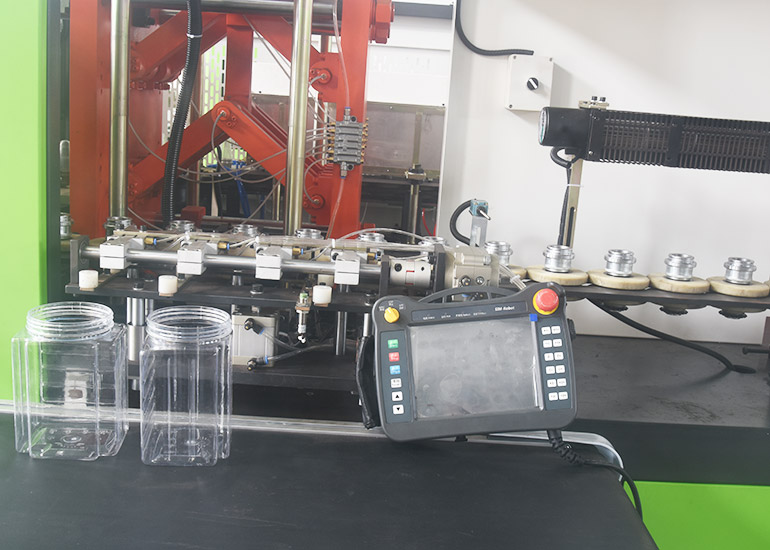

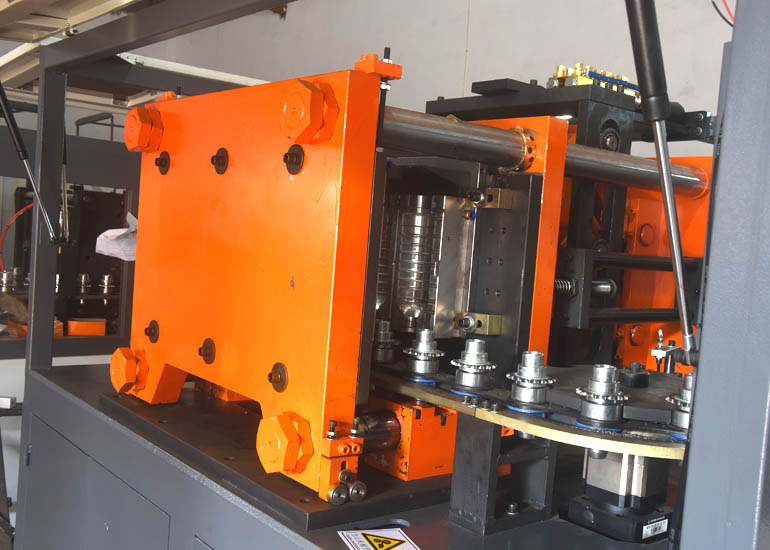

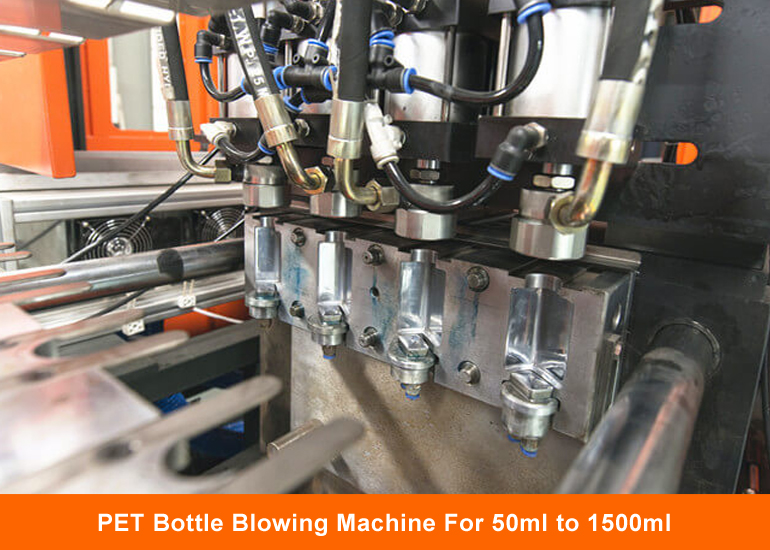

Where to buy PET bottle blowing machine

Where can I buy a bottle blowing machine, where is the automatic bottle blowing machine of good quality, fast and hygienic, and where is the bottle blowing machine with good stability? Is the quality of China PET bottle blowing machine good? How about after-sales? how much is pet bottle blowing machine ?

Read More

What material can be used for hollow blow molding machine

The plastic varieties used in the hollow blow molding machine include polyethylene, polyvinyl chloride, polypropylene, polystyrene, linear polyester, polycarbonate, polyamide, cellulose acetate and polyacetal resin.

Read More

How much product can the automatic bottle blowing machine blow, and what is the output?

Output: The number of bottles that can be blown per unit time, also known as production capacity. Generally, the small automatic blow molding machine can blow 2000-2500 bottles per hour, while the high-speed automatic blow molding machine can blow 9000-12000 bottles per hour. The output of the automatic bottle blowing machine is determined by the weight and caliber of the preform. The heavier the p...

Read More

What is a bottle blowing machine?

The bottle blowing machine is a kind of plastic particles by blow molding process will be made into hollow container equipment, currently more common types include, forming a PP and PE hollow extrusion blow machine, using PET, PC or PP two molding injection stretch blow molding machine, and the newly developed multilayer hollow extrusion blow molding and stretch blow molding.

Read More

What is the feeding system of the bottle blowing machine

With the development of high-speed, high-efficiency, mechanization, and automation of the bottle blowing machine, its feeding method has gradually changed from manual to automatic. Several common forms are introduced below.

Read More

What are the characteristics of PET preform materials? What should I pay attention to when blowing a bottle?

Everyone has seen plastic bottle caps. Every time we unscrewed a sealed bottle cap, did you find that there is a ring between the bottle cap and the plastic bottle that connects the two parts. In fact, this small circle is called PET preform, it is a typical injection molding product, easy to transport, mostly plastic material, uniform texture, and good insulation.

Read More

What is the Difference between Full-Auto Blowing Machine and Semi-automatic Blowing Machine

Blowing machine is a kind of equipment for making plastic granules into hollow containers by blow molding process. There are two kinds of blow molding machines. One is a one-shot hollow extruding blower using PP and PE, and the other is using PET.

Read More